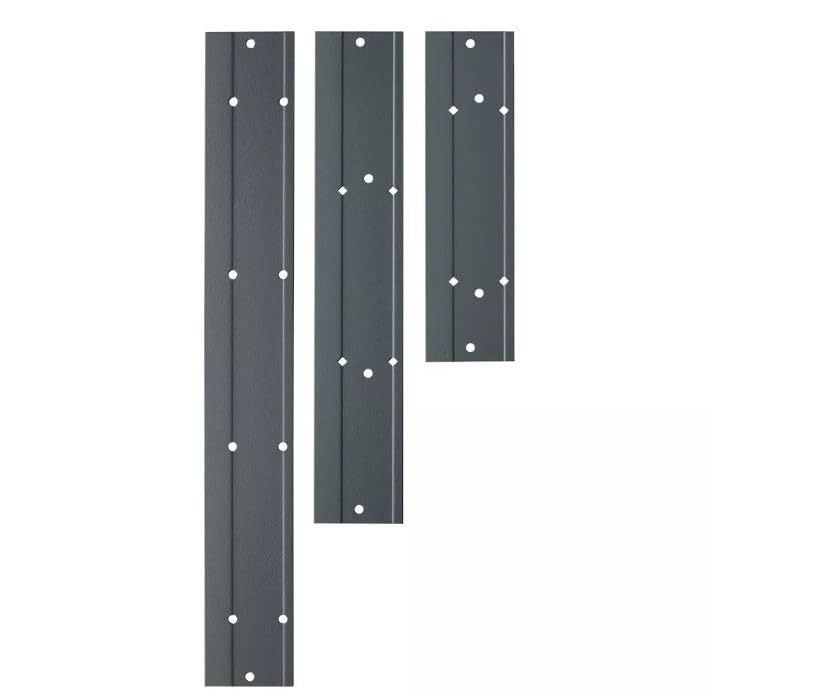

Hi-power motor is adopted with all drive axes, maximum speed up to 20,000 rpm;Input voltage/Current /Power: 12V/3A/36W;Input Voltage of Switch Power Supply: 110V-240V The largest diameter of processed material: 50mm (Positive Jaw Gripping Range: 3mm-30mm,Opposite Jaw Gripping Range: 3mm-50mm;Kind Notice: manual measurement, there will be 2-3mm error.) The length of processed material: 150mm;The chuck and collets is 1 to 6mm;X-axis slider travels:150mm;Machine size:310mm*100mm*150mm;Bottom plate size: 315mm*200mm*17mm The processed materials can be clamped by three-jaw chuck / collets, its maximum diameter is 50mm The motor case and headstock of all-metal machine tools is jointed completely. Main parts configure with metal structure and no plastic components in the whole machine body, such as motor box, headstock, hand wheels, slider, 3-jaw chunk/4-jaw chunk, turning tools clamping jaw, machine bed, gear, side cover, working table, connection piece, tailstock, countershaft, drive belt cover etc. Fan built-in motor is featured with ultra-quiet & high rotary speed. That's special customized option for motor cooling & effective work.The most parts of machine tools are dealt with two surface treatment methods of electroplating and ink-jet anodized to make appearance more cleaning & glorious, lasting rust-proof. Machine bed is made of Europe standard T-type aluminum material, moving more precisely &smoothly.3C quality assured transformers have the function of over-current, over-voltage and over-heat protection.To improve the stability and service life, the connection block be fixed by square nuts, which avoid screw loosing after long time vibration. The connection block adopts dovetail structure, which matches with each slot of the machine tools parts to enhance its performance and accuracy.Versatile application: The turning tools of mini metal lathe are made of steel material, which can be perfectly used to process the soft metal (gold, silver, copper & aluminum), acrylic and engineering plastics etc. By adding some loose-preventing nuts on the side of small& big slider, not only avoid the gap after excessive vibration, but also improve the processing accuracy.The chuck is fixed by a hexagon nut to increase the tightness of the clamping tools (such as drill bits, cutters, wood-turning lathe driver). The whole hand wheel is made of super alloy material, which be assembled in X, Z axis and tailstock. Featuring with 0.02mm scale line, the hand wheel increases the precision when processing. (The scale lines are molded at one time, aren't sticky label)3/4 semi-circular structure designed hand wheel, that's quite convenient for dismantling connection blocks. Technical Parameter:

1.Hi-power motor is adopted with all drive axes, maximum speed up to 20,000 rpm

2.Input voltage/Current /Power: 12V/3A /36W

3.Input Voltage of Switch Power Supply: 110V - 240V

4.The largest diameter of processed material: 50 mm (Positive Jaw Gripping Range: 3mm-30mm,Opposite Jaw Gripping Range: 3mm-50mm;Kind Notice: manual measurement, there will be 2-3mm error.)

5.The length of processed material: 150 mm

6.The chuck and collets is 1 to 6mm

7.X-axis slider travels: 150mm

8. Center height-50mm, center distance- 150 mm

9.Machine size:310mm*100mm*175mm

Operation:

Firstly locate the center of work piece by center finder, Use 2 iron rods to unscrew the three-jaw chuck and place one end of the work piece into middle of the chuck.Tighten the chuck and rotate the hand wheel at the other end to push the live center into the center of the workpiece tightly.And then, tighten the tailstock and fix the screw, so as to fix the work piece.

Turn on the lathe, move the small slider in the Y axis direction to control the feed,move the big slider in the X axis direction to control the processing position.

Notes:

If the work pieces are notconcentric and haveimaginary circles, remove the outerimaginary circle.

Tool setting: before processing, insert the turning tool into the turning tool clamping jaw and move the slider to adjust the turning tool into the same horizontal line with the live center& middle of three jaw chunk.

If processing wood, the cutting amount should be less than 2mm per time;If processing aluminum or copper, the cutting amount should be less than 1mm per time.Otherwise, the motor will stop working and start self-protection.

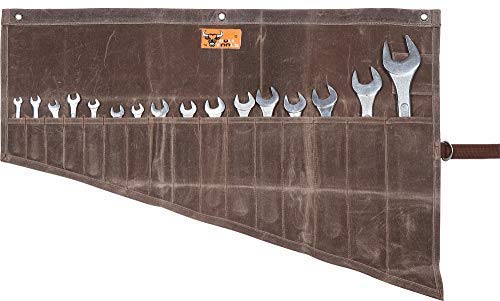

Package Includes:

- 1 x Mini Lathe

- 1 x Set of Accessories

- 1 x Power Adapter

- 1 x Workbench Plate

- 1 x Manual

Q1: What's the usage of ZR miniature machine tools?

The miniature machine tools have the same features as big industrial machines, the only differences are their size and the 12V drive. You can use it for DIY model making and some little crafts, which is also able to process hard wood, soft metal, alloy etc...Based on its modularity and the child friendly use, that's ideal& creative product to inspire children hand-on skill&innovative ability.

Q2: Is it easy to assemble and operate the miniature machine tools?

What we provided is the installed complete machine tools, meanwhile, there is full set of English manual & guide videos to show you how to use it smoothly. If you still have any query, please contact our online customer service.

Q3: How about the after sales service?

Free spare parts and one year warranty